- Home Page

- Company Profile

-

Our Products

- Reverse Osmosis Plant

- Jar Washing and Filling Machines

- Mineral Water Plant

- Bottle Filling Machine

- Soda Soft Drink Plant

- Water Softening Plant

- Demineralization Plants

- EDI / Electrodeionization Process Plant

- Ultra Filtration System

- Pet Blow Moulding Machine

- BOPP Labelling Machine

- Bulk Shrink Machine

- Effluent Water Treatment Plant

- UV / Ultraviolet Disinfection System

- Swimming Pool Filtration Plant

- Pressure Booster System

- Sewage Treatment Plant

- ISI/BIS Laboratory

- Batch Coding Machine

- Glass Filling Machine

- Mixed Bed System

- Water Chiller

- Water Cooler

- Mixed Bed Deionizer

- Soda Filling Machine For Pet Bottle

- Mineral Water Filling Machines

- Bulk Shrink Wrapping Machine

- Swimming Pool Sand Filtration System

- UV Disinfection System

- More Info

- Contact Us

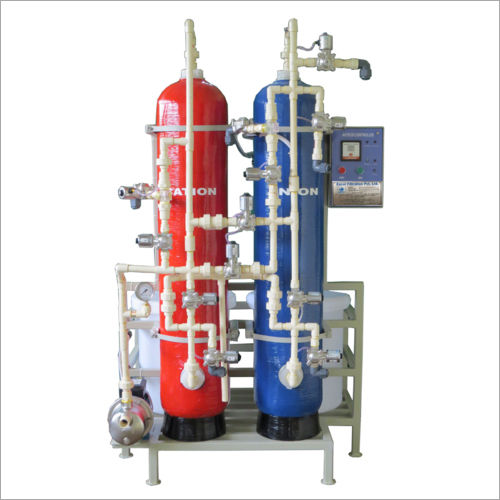

Demineralization Water Plant

210000 INR/Unit

Product Details:

- Voltage 220V/50Hz Watt (w)

- Water Source Ground Water

- Click to view more

X

Demineralization Water Plant Price And Quantity

- 1 Unit

- 210000 INR/Unit

Demineralization Water Plant Product Specifications

- Ground Water

- 220V/50Hz Watt (w)

Demineralization Water Plant Trade Information

- 1 Unit Per Day

- 30 Days

Product Description

In the demineralization process, mineral salts are removed from Water by utilizing the ion exchange process. De mineralized Water doesnt have any dissolved minerals and is the result of one of the following processes:

Why water is de mineralized before using it for industry purpose?

Distilled water contains dissolved silica. If distilled water is fed to boiler and turbine section it will unbalance the temperature in boiler section from higher to lower temperature or lower to higher temperature. Distilled water contains dissolved silica. DM water is applicable to boilers feed Water, Textiles, Pharmaceuticals, Chemicals, Breweries, Swimming pools, Potable Water, Hospitals, Automobile, and Battery, Fertilizers.

Why to choose us?

Our company delivers a high-quality Demineralization Water Plant to clients. The demineralization plant utilizes the ion-exchange process for removing mineral salts from water. This plant can be provided in customized options in order to meet the requirements of clients. Our company is known as one of the trusted Demineralization Water Plant Exporters. The resins we use are ideal for removing the ionic impurities. It remains stable over the wide range of temperatures and can be regenerated.

Working Principle

A DM Water System produces water that is mineral free by operating on the ion exchange, Degasification, and polishing principles. Demineralized water, also called de-ionized water has no mineral ions, like cations of iron, sodium, copper, calcium, etc. Anions like sulfate, chloride, nitrate, etc., are common ions that are present in Water. Deionization process makes use of specially created ion exchange resins that provides ion exchange site for the mineral salts replacement in water with water creating H+ and OH- ions.

De-mineralization technology is the proven water treatment process.

Ion exchange process is ideal for water treatment and purification. (An ion is an atom or atoms group with an electric charge. Positively-charged ions are known as cations and are generally metals; negatively-charged ions are known as anions and are generally non-metals). Ion-exchange is quick, reversible process that replaces impurity ion in the water by ions released by an ion-exchange resin.

Two basic resin types:

The two-bed deionizer comprises two vessels, one contains an anion resin in the hydroxyl (OH-) form, while the other contains a cation-exchange resin in the hydrogen (H+) form. As the water flows through the cation column, cations are exchanged for hydrogen ions. For every Na+ and alike monovalent cation, one hydrogen ion is exchanged; and for every Ca2+, Mg2+ or any other divalent cation, two hydrogen ions are exchanged in order to maintain the electrical balance of the water. During anion-exchange, same principle is usually applied. The anion column is the next from where the decationized water flows and the negatively charged ions are exchange for hydroxide ions. Water is formed when these are then combined with the hydrogen ions.

Mixed Bed Deionization

The anion-exchange resins and cation-exchange resins are mixed throughly and contained in a single pressure vessel. In single column, the mixture forms a mixed-bed deionizer equivalent to a lengthy series of two-bed plants. In comparison to two bed plant, the water quality from a mixed-bed deionizer is higher. Mixed-bed deionizer is sensitive to impurities in the water supply, therefore involves a regeneration process that allows for efficient purification of incoming feed water. Mixed-bed deionizer further purifies water once treated by a RO unit or two-bed deionizer.

Our de-mineralizing plant is uniquely designed for utmost surface area use, uniform spacing and linear velocity across the resin bed. This enables effective contact time between water and resin bed, and yield soft water, as well as prevent any precipitation and formation of scale on the surface of heat exchanger and any other process equipment in which water is used for further application.

Resin takes up the impurity ions, which need to be timely regenerated for restoring them to the original ionic form. Regeneration involves separation of resin by backwash, separate regeneration with 5% HCl and 5% NaOH, and blending after washing.

- Distillation

- Deionization

- Electro-dialysis

- Membrane filtration (reverse osmosis or nano filtration)

- Or other technologies

Why water is de mineralized before using it for industry purpose?

Distilled water contains dissolved silica. If distilled water is fed to boiler and turbine section it will unbalance the temperature in boiler section from higher to lower temperature or lower to higher temperature. Distilled water contains dissolved silica. DM water is applicable to boilers feed Water, Textiles, Pharmaceuticals, Chemicals, Breweries, Swimming pools, Potable Water, Hospitals, Automobile, and Battery, Fertilizers.

Why to choose us?

Our company delivers a high-quality Demineralization Water Plant to clients. The demineralization plant utilizes the ion-exchange process for removing mineral salts from water. This plant can be provided in customized options in order to meet the requirements of clients. Our company is known as one of the trusted Demineralization Water Plant Exporters. The resins we use are ideal for removing the ionic impurities. It remains stable over the wide range of temperatures and can be regenerated.

Working Principle

A DM Water System produces water that is mineral free by operating on the ion exchange, Degasification, and polishing principles. Demineralized water, also called de-ionized water has no mineral ions, like cations of iron, sodium, copper, calcium, etc. Anions like sulfate, chloride, nitrate, etc., are common ions that are present in Water. Deionization process makes use of specially created ion exchange resins that provides ion exchange site for the mineral salts replacement in water with water creating H+ and OH- ions.

De-mineralization technology is the proven water treatment process.

Ion exchange process is ideal for water treatment and purification. (An ion is an atom or atoms group with an electric charge. Positively-charged ions are known as cations and are generally metals; negatively-charged ions are known as anions and are generally non-metals). Ion-exchange is quick, reversible process that replaces impurity ion in the water by ions released by an ion-exchange resin.

Two basic resin types:

- Cation exchange resins: These release hydrogen (H+) ions or other positively charged ions in exchange for impurity cations in water.

- Anion exchange resins: These release hydroxyl (OH-) ions or other negatively charged ions in exchange for impurity anions in water.

- Cation exchange resins can be used for softening water by Base Exchange

- Anion-exchange resins can be used for removing nitrate or organic scavenging

- Cation exchange resins and anion-exchange resins can be combined for removing virtually all the ionic impurities in the feed water. This process is called as de-ionization. Water de-ionizers purification process results in high quality water. This high quality water free from ionic contaminants are demanded in labs and industrial applications. De-ionization is a reliable method for the production of quality water.

- Ionization can be widely divided into Two bed deionization and Mixed bed deionization.

The two-bed deionizer comprises two vessels, one contains an anion resin in the hydroxyl (OH-) form, while the other contains a cation-exchange resin in the hydrogen (H+) form. As the water flows through the cation column, cations are exchanged for hydrogen ions. For every Na+ and alike monovalent cation, one hydrogen ion is exchanged; and for every Ca2+, Mg2+ or any other divalent cation, two hydrogen ions are exchanged in order to maintain the electrical balance of the water. During anion-exchange, same principle is usually applied. The anion column is the next from where the decationized water flows and the negatively charged ions are exchange for hydroxide ions. Water is formed when these are then combined with the hydrogen ions.

Mixed Bed Deionization

The anion-exchange resins and cation-exchange resins are mixed throughly and contained in a single pressure vessel. In single column, the mixture forms a mixed-bed deionizer equivalent to a lengthy series of two-bed plants. In comparison to two bed plant, the water quality from a mixed-bed deionizer is higher. Mixed-bed deionizer is sensitive to impurities in the water supply, therefore involves a regeneration process that allows for efficient purification of incoming feed water. Mixed-bed deionizer further purifies water once treated by a RO unit or two-bed deionizer.

Our de-mineralizing plant is uniquely designed for utmost surface area use, uniform spacing and linear velocity across the resin bed. This enables effective contact time between water and resin bed, and yield soft water, as well as prevent any precipitation and formation of scale on the surface of heat exchanger and any other process equipment in which water is used for further application.

Resin takes up the impurity ions, which need to be timely regenerated for restoring them to the original ionic form. Regeneration involves separation of resin by backwash, separate regeneration with 5% HCl and 5% NaOH, and blending after washing.

Features of Demineralization Water Plant:

- Durable and rigid

- Fast availability

- Clearly marked operating step on the valve eliminates the chances of error in the operating sequence

- Single valve assembly together with simple frontal Piping and distribution collecting systems

- Number of standard models

- User friendly, minimal maintenance and easy installation

- Sturdy construction and long service life

- Technical resin application support

- Custom packaging to meet the volume requirements of clients

Applications of Demineralization Water Plant:

- Pre Treatment of Mixed Bed unit for High Purity

- Swimming pools

- Potable Water, Hospitals, Automobile, and Battery

- Fertilizer Industry

- De-gasifier

- Textile Industries

- Pharmaceutical Industries

- Chemical Industries

- Food and Beverage Industries

- Post Treatment of RO plant

- Manual/Automatic Plants

- Power Plant

- Oil & Gas sector

Product details

Maximum Working Pressure | 3.5 Kg/cm2 |

Flow rate | 100 m3/hour |

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free